Thanks to the long experience of the company, we can offer the best solutions to our clients.

Do not hesitate to contact us for more information.

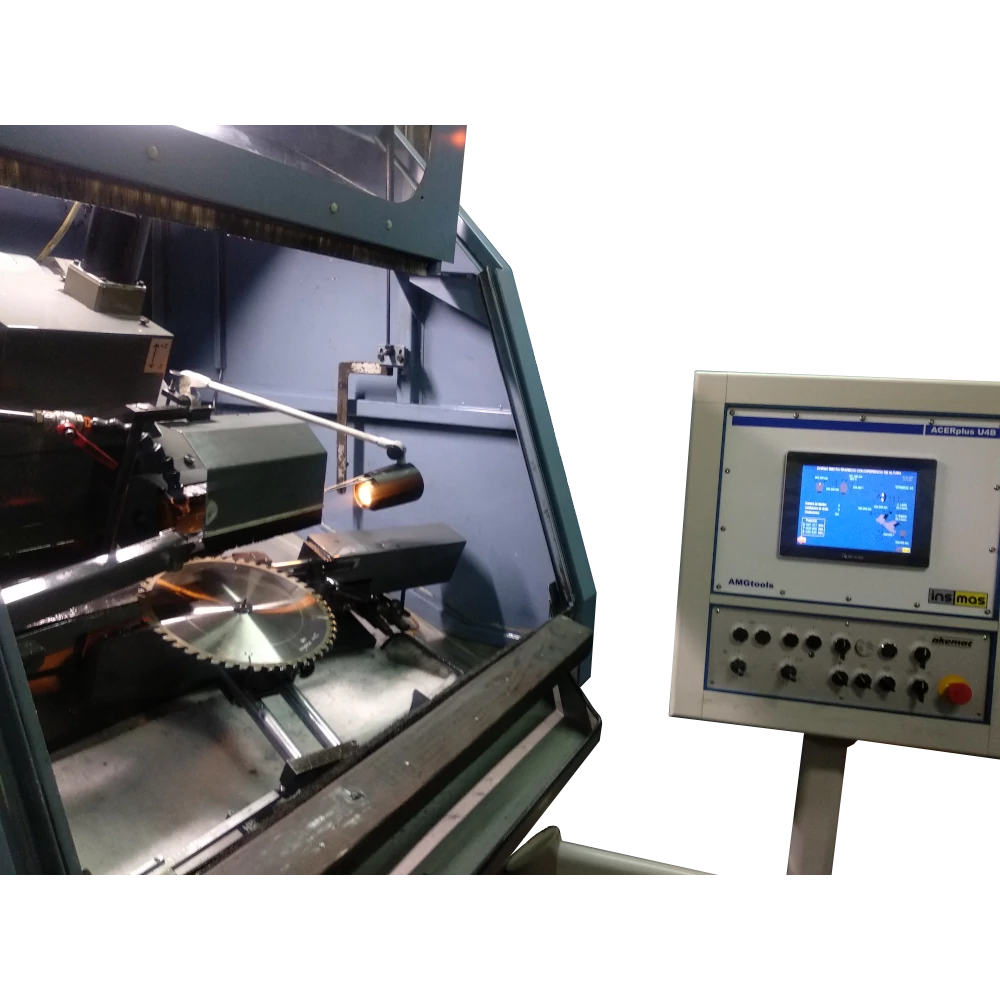

Retrofit AKE U4/U4B

Retrofit for AKEMAT Ake U4/U4B.

Thanks to the retrofit, you will gain in working power by being able to sharpen discs in a much easier way.

Another advantage is the replacement of the discontinued controls with a Siemens control and a touch terminal.

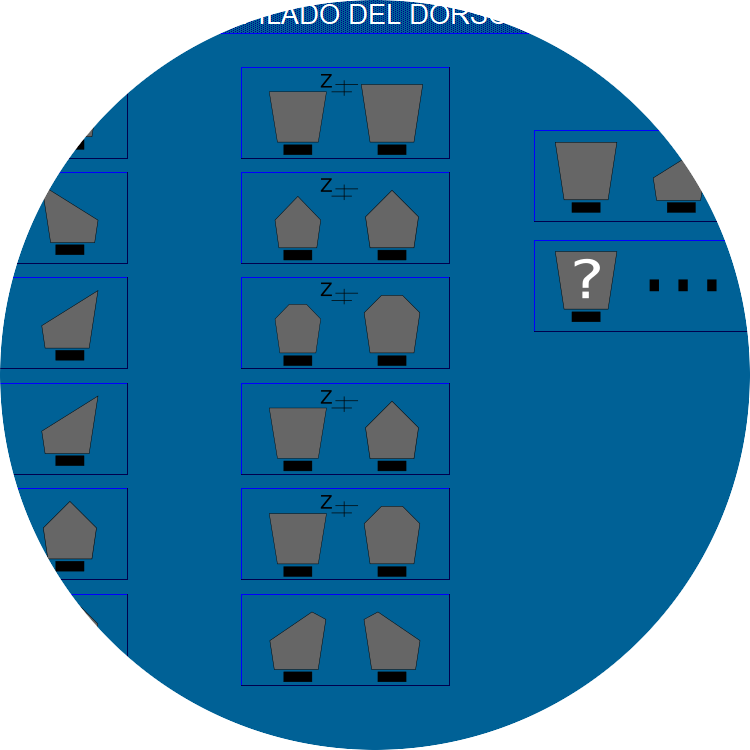

Sharpening the back

Thanks to retrofit, it is now possible to make all types of teeth.

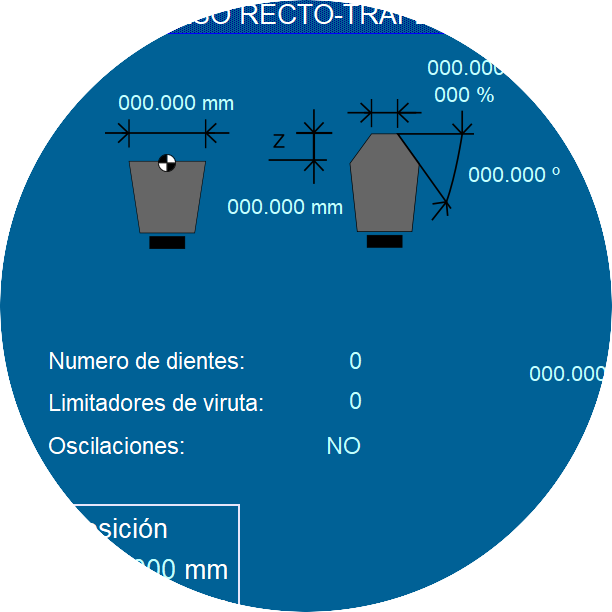

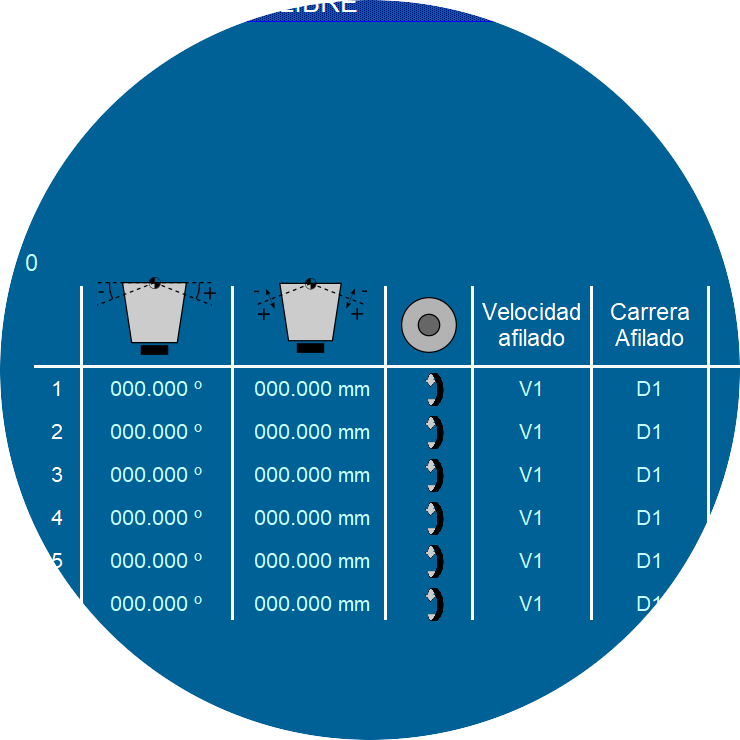

Trapezium - flat

Programming example of a flat trapezium disk.

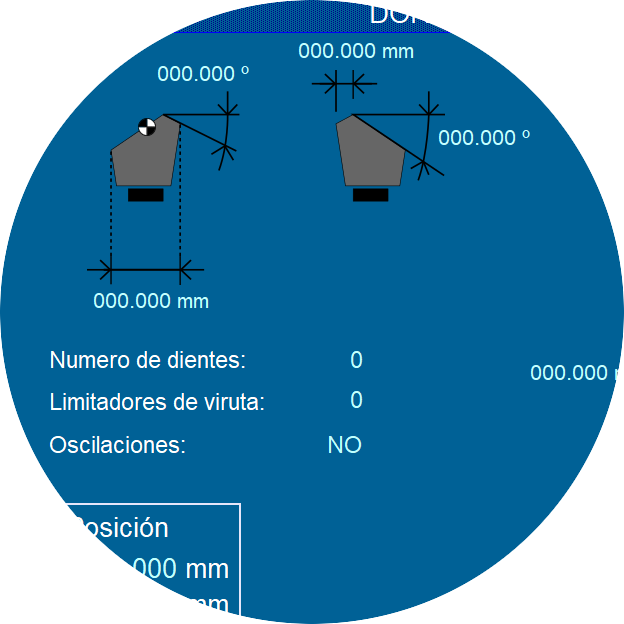

Asymmetric

Programming example of an asymmetric disk.

Free group

Free disk programming.

Free teeth can also be defined in this type of program.

Free tooth

Programming a free tooth.

Technical characteristics

| Controlled axes | 3 |

| Replacement of the PC unit, display, PLCs and Step10 controllers with our ACERplus control | Yes |

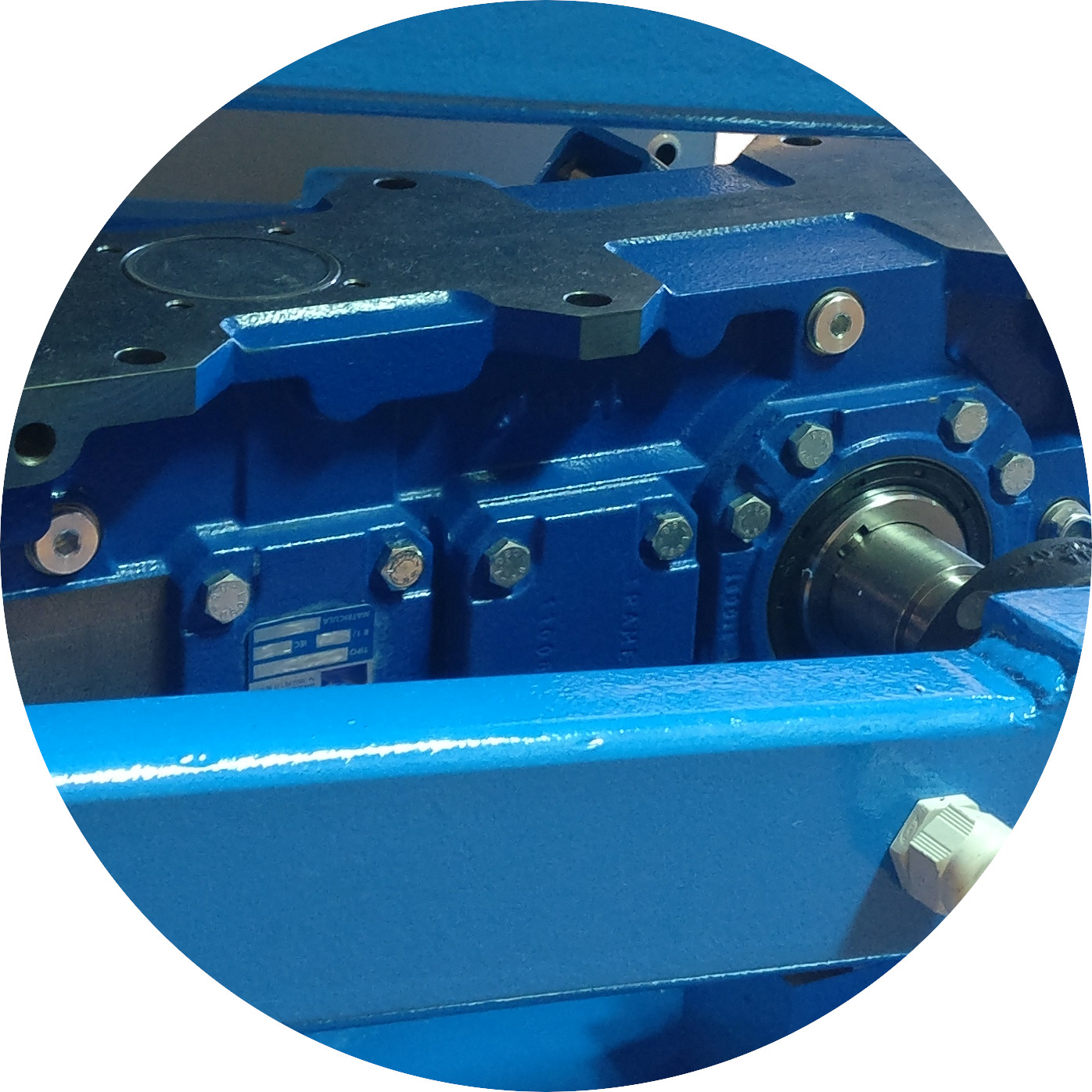

| Replacement of the X axis motor / regulator assembly with a servomotor | Yes |

| Replacing the Y axis motor / driver assembly with a servomotor | Optional |

| Replacing the Z axis motor / driver assembly with a servomotor | Optional |

| Activation of sharpening spindle by frequency converter | Optional |

| Standard programs for machining the back ¹ | Yes |

| Special program package for Group teeth and Multi-surface machining ² | Yes |

| Special repair program | Optional |

| Special oscillation program | Optional |

| Special program for machining the base sheet | Optional |

| Remote Control Unit ³ | Yes |

¹ Flat, Right phase, Left phase, Alternatives, Point, Trapezoid, Alternatives inclined on both sides and Geometries with height difference (Flat / Flat, Point / Point, Trapezoid / Trapezoid, Flat / Point, Flat / Trapezoid).

² Package for group teeth and multi-surface machining, repair program, oscillation program and base sheet machining.

³ Connection via Ethernet or WIFI, to the InsMas IoT cloud. Allows InsMas technicians to view the status of the machine online to help solve possible faults, make modifications and / or transfer new special programs. Its installation depends on the client’s facilities.

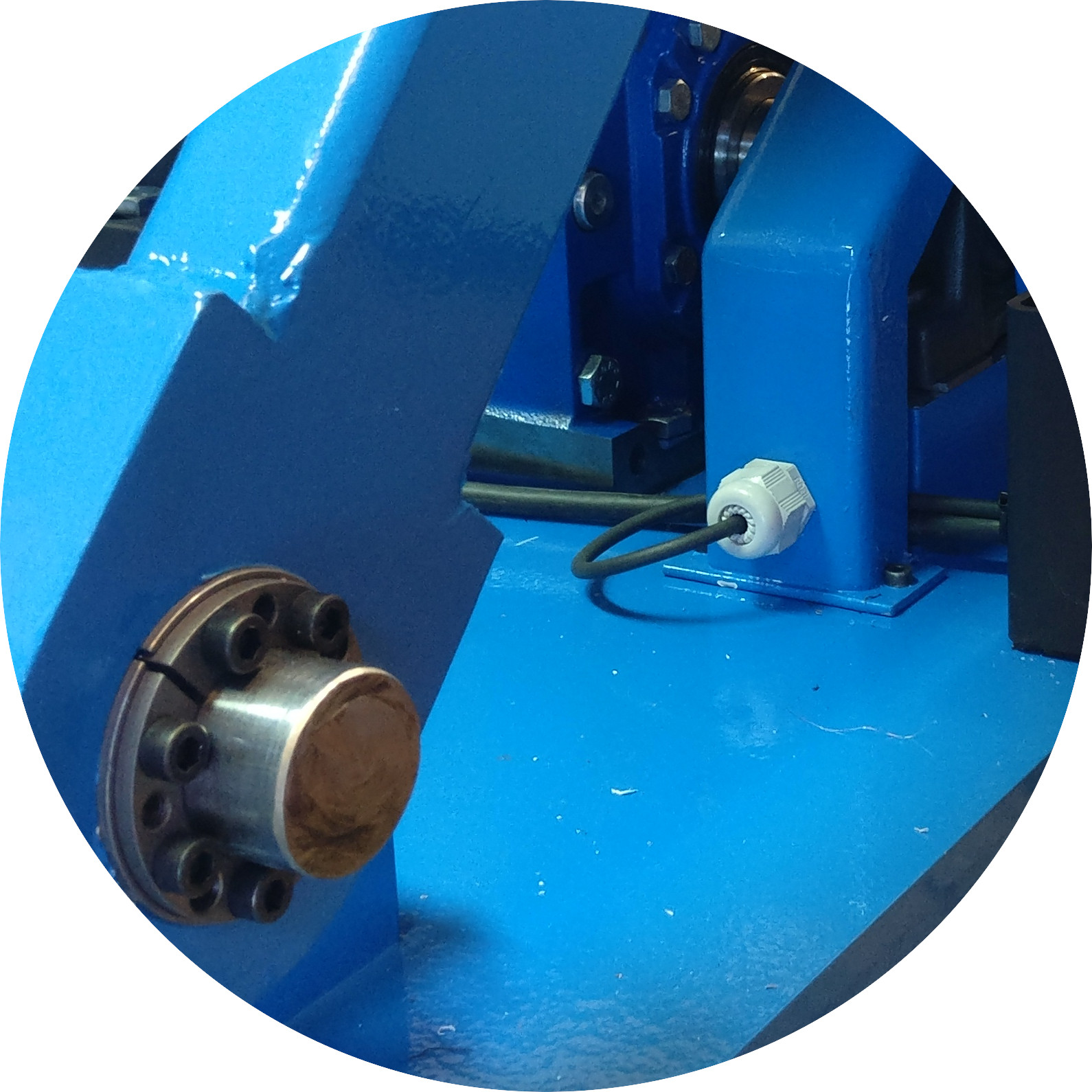

Retrofit MVM K250

Retrofit for straight blade sharpener of the MVM brand.

Thanks to the retrofit, you will gain in working power by being able to sharpen blades in a much easier way.

Another advantage is the replacement of the discontinued controls with a Siemens control and a touch terminal.

Technical characteristics

| Controlled axes | 1 |

| Cart with encoder | Yes |

| Orientation of the magnetic plate by servomotor | Yes |

| Replacement of the control unit and control panel with our ACERplus control | Yes |

| Program for grinding blades in automatic mode | Yes |

| Remote Control Unit ¹ | Yes |

¹ Connection via Ethernet or WIFI, to the InsMas IoT cloud. It allows InsMas technicians to see the status of the machine online to help solve possible faults, make modifications and / or transfer new special programs. Its installation depends on the client’s facilities.

Feeder

Automatic feeder with conveyor belt

Automatic conveyor belt feeders adaptable to any machine

- Quick and convenient part feeding

- Very robust and fast

- Painted or stainless steel construction

- Lifting and drag speed regulators

Assembly of electrical panels

From design to final testing, through assembly, installation and documentation.

Feel free to request information.